What is biodiesel? How is biodiesel made?

Biodiesel is a clean and renewable energy. It is kind of liquid fuel made of oil crops like soybean and rapeseed, oil tree fruits like oil palm and yellow wood, oil aquatic plants like engineered microalgae, and animal oil, waste cooking oil. It is a substitutes for petroleum and diesel.

Biodiesel are used in the same way as diesel. But it is not directly used as fuel. It is usually mixed with diesel. Biodiesel can be used in small and large diesel engine, tractors, and diesel cars. Burning diesel can reduce the hydrocarbon emission by 55%-60%, PM 20%-50%, CO 45%, PAHs 75%-85%. The application of biodiesel can relieve energy shortage, and reduce pollution emission.

Advantages of biodiesel

Environmental friendliness

Biodiesel has low sulfur content, so the SO2 and sulfide emission is low. It can cut 30% (70% with catalyst) sulfur emission than diesel. Besides, biodiesel doesn’t contains polluting aromatic paraffin, so the exhaust gas does less harm to human body than diesel.

Good lubricity

Using biodiesel can lower the wear rate of injection pump, engine cylinder body and connecting rod. It can prolong their working life.

High safety

Biodiesel has high flash point. It doesn’t belong to hazardous articles, so it is convenient for transportation and storage.

Good combustibility

High hexadecane content makes biodiesel better combustibility than diesel. The combustion residue has slight acidity, which can prolong the working life of catalyst and engine oil.

Renewable

Biodiesel is a renewable energy, while petroleum has certain quantity of reservation. We don't need to worry the biodiesel would run out some day.

Easy to use

You don’t need to upgrade the diesel engine. Just feed the biodiesel to it. Besides, there is no need of special fuel-servicing equipment, storage device or staff training.

Mixed use

By mixing biodiesel with petroleum diesel in certain proportion, users can reduce the diesel consumption, improve the power performance, and reduce tail gas pollution.

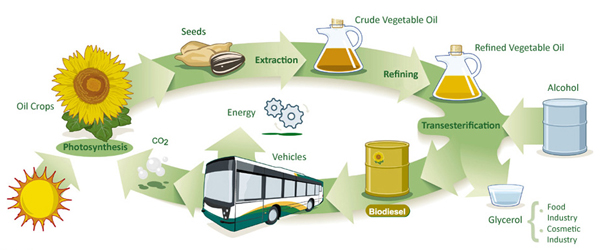

How is biodiesel made

Catalytic synthesis method

Currently, most biodiesel is made by chemical method. Animal and vegetable oils have transesterification reaction with low carbon alcohol such as methanol or ethanol under high temperature and acid and alkaline catalysts. It is produced by common oil production equipment, with 10% glycerin as by-products.

Biological enzyme method

Biological enzyme method is to use lipase to induce transesterification reaction between animal fats and low carbon alcohol, and produce fatty acid methyl ester and ethyl ester. The new technique can transform animal and vegetable oil into biodiesel at room temperature, and the productive rate can be more than 90%.

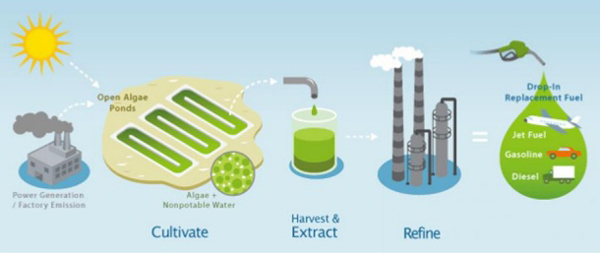

Engineered microalgae method

Engineered microalgae method is to transform the physiological structure with genetic engineering technology to increase their productivity and oil content. National renewable energy laboratory (NREI) can increase the lipid content by 60%. The lipid is extracted with normal hexane.

The application of biodiesel around the world

Currently, countries all over the world have taken part in the development and application of high-efficiency and pollution-free biomass energy, especially in developed countries. Europe has become the major production area of biodiesel.

America is the earliest country engaged in biodiesel development. An America scientist Graham first used flaxseed oil in engines, and defined renewable fatty acid monoester as biodiesel. In 1984, American and German scientists used fatty acid monoester from animals and plants to take the place of diesel for burning. In 1990, America start to produce biodiesel with soybean oil in small scale. In 1992, biodiesel is proposed as a clean fuel by EIA, who also promote the application of biodiesel. According to American biodiesel association, there have been 171 biodiesel manufacturers by 2008. In 2009, America’s biodiesel production accounts for 17.7% of the world’s total production.

EU is the main place for biodiesel development and application, as well as the market of rapeseed. The production place of biodiesel are Germany, French and Italy. Currently, Germany has been the world’s largest biodiesel manufacturer. It's biodiesel production has reached up to 5 million tons by 2010. All German diesel-powered car can use biodiesel as fuel. EU has carried out regulations that all diesel sold on the market should contain at least 5% biodiesel. French, Italy, Denmark and other European countries have taken part in the competition of biodiesel development. They have made their own development strategy and made great progress in the industrialization of biodiesel.

Japan's biodiesel is mainly from waste cooking oil. Marine products is the main food for Japanese. To fry the seafood, Japan consume 2 million tons of cooking also, which provide abundant raw materials for biodiesel production. Japan started to make waste cooking oil into biodiesel in 1995. It built a 259t/d biodiesel production plant that adopts waste cooking oil as material in 1999. Currently, Japan’s biodiesel production is 400,000t. Japanese civilians contribute their waste oil to the recovery point to support this project. The same as European countries, Japan government lays zero tax to biodiesel, and provide subsidies to gasoline stations who supply biodiesel.

Brazil’s biomass energy develops rapidly by virtue of its agriculture advantages. Besides the promotion of ethanol fuel technology, Brazil also increases the input on biodiesel development. The implement an act that requires to mix at least 2% biodiesel with petrochemical diesel. The main raw materials for the biodiesel in brazil are castor oil, palm oil, soybean oil, cottonseed oil, sunflower oil and corn oil etc.

Future development of biodiesel

Although biodiesel is a renewable and promising energy, it still have some problems currently. The largest dispute is biodiesel’s threaten on food. The application of biodiesel will drive more farmers to plant cash crops, which will increase the food price and cause food crisis.

To prevent this problem, more and more biodiesel is made of special biodiesel plants. For example, Jatropha grows in sterile environment, and it produce large quantities of inedible oil. As mentioned above, scientist is developing technologies to extract oil from seaweeds. Besides, using waste oil is an economical and environmentally friendly way.

Engineered microalgae