» fuso de alta freqüência para o centro de usinagem do torno paralelo

Dados técnicos do motor do eixo:

Spindle type |

Speed |

Motor |

Lub |

Cool |

Joint of Nose |

Bearing type |

Feature |

|||

KW |

V |

A |

Hz |

|||||||

ADS0820-30Z/1.8 |

30000 |

1.8 |

220 |

7 |

500 |

grease |

water |

IS020 taper hole |

2×B7005C/P4 |

with sensor & device loosen broaching tool |

1×7003C/P4 |

||||||||||

ADS1130-18Z/3.2 |

18000 |

3.2 |

220 |

11.6 |

300 |

grease |

water |

BT30 taper hole |

2×B7007C/P4 |

with sensor & device loosen broaching tool |

1×7005C/P4 |

||||||||||

ADS1130-18Z/3.2J |

18000 |

3.2 |

220 |

11.6 |

300 |

grease |

water |

BT30 taper hole |

2×B7007C/P4 |

with encoder & device loosen broaching tool |

1×7005C/P4 |

||||||||||

ADS1230-24Z/5 |

24000 |

5 |

350 |

10.5 |

400 |

grease |

water |

BT30 taper hole |

2×B7007C/P4 |

with sensor & device loosen broaching tool |

2×7005C/P4 |

||||||||||

ADS1430-4-12Z/1.5 |

4000 |

1.5 |

220 |

5.7 |

133 |

grease |

water |

BT30 taper hole |

2×VEX55/P4 |

with sensor & device loosen broaching tool |

12000 |

380 |

400 |

2×VEX40/P4 |

|||||||

ADS1425-18/3 |

18000 |

3.6 |

350 |

8.5 |

600 |

grease |

water |

IS025 taper hole |

2×B7008C/P4 |

with device loosen broaching tool |

2×7008C/P4 |

||||||||||

ADS1530-18Z/7.3 |

18000 |

7.3 |

293 |

19 |

300 |

grease |

water |

BT30 taper hole |

2×7007C/P4 |

with sensor & device loosen broaching tool |

2×7006C/P4 |

||||||||||

ADS1530-18Z/7.3J |

18000 |

7.3 |

293 |

19 |

300 |

grease |

water |

BT30 taper hole |

2×7007C/P4 |

with encoder & device loosen broaching tool |

2×7006C/P4 |

||||||||||

ADS1520-24Z/7.3 |

24000 |

7.3 |

293 |

19 |

400 |

grease |

water |

IS020 taper hole |

2×7006C/P4 |

with sensor & device loosen broaching tool |

2×7005C/P4 |

||||||||||

ADS1640-6Z/6 |

6000 |

6 |

380 |

11.7 |

200 |

grease |

water |

BT40 taper hole |

3×7014C/P4 |

with sensor & device loosen broaching tool |

2×7210C/P4 |

||||||||||

ADS1740-2Z/2.2 |

2000 |

2.2 |

350 |

5.9 |

66.7 |

grease |

water |

BT40 taper hole |

3×B7015C/P4 |

with encoder & device loosen broaching tool |

2×7011C/P4 |

||||||||||

ADS1740-3-9Z/3.7J |

3000 |

3.7 |

220 |

12.5 |

100 |

grease |

water |

BT40 taper hole |

2×VEX65/P4 |

with encoder & device loosen broaching tool |

9000 |

380 |

11.3 |

300 |

2×E250/P4 |

||||||

ADS1740-8Z/6 |

8000 |

6 |

350 |

12.8 |

267 |

grease |

water |

BT40 taper hole |

2×7014CAT/P4 |

with sensor & device loosen broaching tool |

2×7209CAT/P4 |

||||||||||

ADS2040-3-10/5.5 |

3000 |

5.5 |

220 |

19.4 |

100 |

grease |

water |

BT40 taper hole |

3×VEX65/P4 |

with encoder & device loosen broaching tool |

10000 |

380 |

300 |

2×VEX55/P4 |

|||||||

ADS2040-3-10/7.5 |

3000 |

7.5 |

208 |

25 |

100 |

grease |

water |

BT40 taper hole |

3×VEX65/P4 |

with encoder & device loosen broaching tool |

10000 |

380 |

333 |

2×VEX55/P4 |

|||||||

ADS2940-1.5-10/11 |

1500 |

11 |

220 |

42 |

100 |

grease |

water |

BT40 taper hole |

3×VEX65/P4 |

with encoder & device loosen broaching tool |

10000 |

380 |

333 |

2×VEX55/P4 |

|||||||

ADS2940-1.5-10/15 |

1500 |

15 |

220 |

56 |

100 |

grease |

water |

BT40 taper hole |

3×VEX65/P4 |

with encoder & device loosen broaching tool |

1000 |

380 |

333 |

2×VEX55/P4 |

|||||||

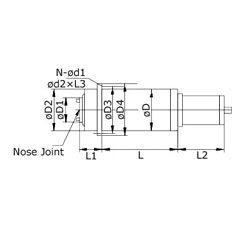

Physical Dimension of Spindle Motor:

Spindle Modelo |

Dimensions (mm) |

|||||||||

D |

D1 |

D2 |

D3 |

D4 |

L |

L1 |

L2 |

N-d1 |

D2×L3 |

|

ADS0820-30Z/1.8 |

80 |

25 |

60 |

-- |

-- |

312 |

-- |

-- |

-- |

-- |

ADS1130-18Z/3.2 |

110 |

34 |

108 |

-- |

-- |

217 |

-- |

-- |

-- |

-- |

ADS1130-30Z/3.2J |

110 |

34 |

83 |

-- |

-- |

238 |

-- |

-- |

-- |

-- |

ADS1230-24Z/5 |

120 |

34 |

119 |

140 |

165 |

335.5 |

50 |

-- |

-- |

-- |

ADS1430-4-12Z/15 |

140 |

53.3 |

140 |

160 |

180 |

325 |

70 |

90 |

8-Φ9 |

Φ14×9 |

ADS1425-18/3 |

140 |

37 |

95 |

163 |

186 |

208 |

87 |

108 |

6-Φ9 |

Φ13.5×9 |

ADS1530 |

150 |

34 |

100 |

-- |

-- |

231 |

50.5 |

114 |

-- |

-- |

ADS1530-18Z/7.3J |

150 |

34 |

100 |

-- |

-- |

231 |

50.5 |

144 |

-- |

-- |

ADS1520-24Z/7.3 |

150 |

28 |

112 |

-- |

-- |

254 |

34 |

110 |

-- |

-- |

ADS1640-6Z6 |

160 |

68 |

160 |

180 |

202 |

345 |

150 |

111 |

6-Φ11 |

Φ17×12 |

ADS1740-2Z/2.2 |

170 |

72 |

-- |

195 |

230 |

655 |

65 |

124 |

8-Φ11 |

Φ17×12 |

ADS1740-3-9Z/3.7J |

170 |

62 |

143 |

195 |

230 |

479 |

153 |

181 |

6-Φ12 |

Φ18×10 |

ADS1740-8Z/6 |

170 |

68 |

150 |

190 |

210 |

274 |

130 |

111 |

6-Φ11 |

Φ18×11 |

ADS2040-3-10/5.5 |

200 |

63 |

145 |

225 |

250 |

405 |

135 |

124 |

6-Φ13 |

Φ19×13 |

ADS2040-3-10/7.5 |

200 |

63 |

145 |

225 |

250 |

445 |

135 |

124 |

6-Φ13 |

Φ19×13 |

ADS2940-15-10/11 |

290 |

68 |

180 |

315 |

340 |

375 |

135 |

124 |

6-Φ13 |

Φ19×13 |

ADS2940-1.5-10/15 |

290 |

68 |

180 |

315 |

340 |

405 |

135 |

124 |

6Φ13 |

Φ19×13 |