Application and superiorities of biomass fuel briquette

Introduction of biomass fuel briquette

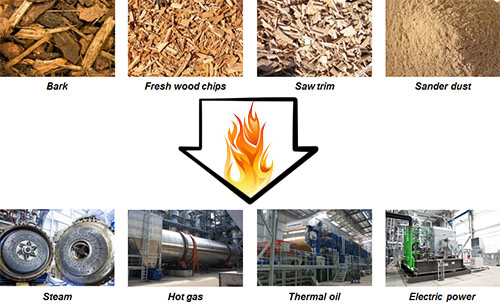

Biomass fuel briquette is made of various kinds of agriculture and forestry waste, such as sawdust, peanut shell, crop straw, rice husk, corn cob, etc. Through crushing, drying, impurity removing and mechanical compression, these biomass materials are molded into briquettes, a clean and environmental-friendly fuel. Biomass fuel briquettes have high density, high burn-out rate, low dust volatilization, and low pollutant emission. As a high quality clean energy, its heat efficiency is up to 45%, which is convenient store and transport.

With the increasing cost for fossil fuel and emphasis on environmental protection, biomass fuel ushers in an unprecedented opportunity. Nowadays, they are widely applied in power generation, industrial boiler, gasifier and crop greenhouse. Meanwhile, they are popular with end-users for heat stove, cook stove and furnace. AGICO is a professional biomass energy solution provider. We manufacture high-efficiency biomass briquette press and complete plant for processing different materials, such as shisha charcoal, straw, brick and coal.

Application of biomass fuel briquettes

The volume and calorific value is comparable to coal. With convenience of storage and transportation, biomass fuel briquettes is an ideal substitute for coal.

Under general condition, biomass fuel briquettes doesn’t generate black smoke when burned. The emission of SO2, NOX and CO is lower than national standard, which is much less than coal. It is able to take the place of coal, gas and liquefied gas and used for home heating, cooking, and industrial production.

Biomass fuel briquette should be used in specialized combustion equipment, who can reduce the emission of SO2, NOX and dust, and achieves high cleanliness and burning efficiency.

For those places where air quality requirement is strict and traditional fuel is in short supply, biomass fuel briquettes is an essential supplement, which should be restricted by the same emission standard as gas.

In practice, setting norms and standard on the application of biomass fuel briquettes and combustion equipment is necessary, which should be strictly carried out.

Superiorities of biomass fuel briquette over coal

The combustion performance of biomass briquette fuel is similar with medium coal, but it bears the following superiorities than coals.

The heat value and dust residue of biomass fuel briquette is 10% lower than medium coal. But because coals cannot burn sufficiently, with 10%-15% combustible components, it is equivalent to biomass fuel briquette in practical use.

Biomass fuel briquette lights more easily than coal. You don’t have to take much time to fire it.

The solid emission of biomass briquette fuel is lower than coal, which alleviate the cost for treating furnace slag and pollutant. Dust account for most of biomass fuel briquette emission, about 0.4%-0.7% of the total weight. On the other hand, burning coals generate dust, alkali and residual coal, which takes up25%-40% of original weight.

Coal is more corrosive to industrial boiler than biomass fuel briquettes. There are large quantity of granular carbon, toxic SO2 and CO. As for biomass fuel briquettes, its main content is C-H organic matters, who doesn’t generate SO2 and CO after burned. The smoke color is lighter than Ringelmann 1st degree. With less pollutant and carbon emission, biomass fuel briquette is internationally known as clean energy.

Adopting biomass fuel briquette in industrial boiler can save your cost and time. Take a 0.5t boiler for example, using biomass fuel briquette takes 34% less time, and costs 11% less time than coals.

Biomass briquette fuel have 8-10 times the burning time compared with bulk materials. And the combustion state is stable and continuous.