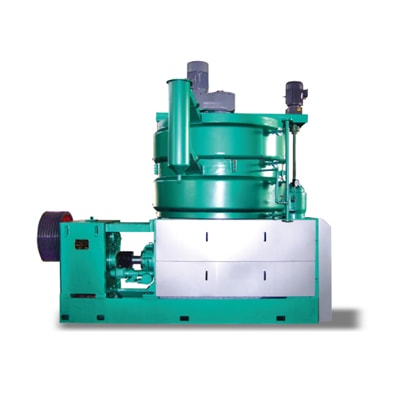

Oil Press

The YZS series oil press is a kind of small oil press. It popularly used at small oil workshop or farm. Of course, it is a good tool for processing biodiesel. The sereies small oil press features simple operation, continuous working and compact structure.

Vegetable Oil Mill

Processing vegetable oil as cooking oil or biodiesel. Business ranging from complete turn-key vegetable oil mill, biodiesel plant to individual sections (such as pre-treatment, pressing, solovent extraction, refining) and prodcuts (such as oil press, filter press, refining tank...).

Biomass Briquette Press

The BZBJ series biomass briquette press is screw type extruder for making biomass briquette bars shaped with square, hexagonal sections etc. As your requirement, we can change the shape made to order. The diameter of briquettes are from 40-130 mm.

Pellet Press

The small pellet press have multi-functions that can be used as good tools to produce pellets at home both for animal feed and pellet fuels. The flat die pellet mill applies to various kinds of biomass materials. With high pressure, it is able to make hard solid pellets efficiently.

Flash Dryer

Flash dryer is a support equipment in biomass briquetting plant and wood pellet plant. It serves to reduce the water content in raw materials, so that they are qualified for making pellets and briquettes. Often flash dryer is used before pellet machine or briquette press.

Biomass Pellet Mill

Pellet Mill have wide application in processing animal feed, wood pellets and other biomass pellet. We undertake the design, manufacture and installation of complete animal feed pellet mill, biomass pellet mill, wood pellet mill with large, middle and small capacity.

Rail fasteners

Agico is a long term partner of CRCC (China Railway Construction Corporation). Our rail fasteners has won CE and ISO9001:2008. The products includes rail joints, railroad spike, rail fastening systems, railroad tie plates, rail clips, hook twin tie plate and rail bolt, etc.

Flour Mill Machine

Flour Mills is our new developed medium flour milling machines. It adopts double arc flank profile belt. The series flour milling machine features balance transmission, low noise, no oil dirty, unique roll bearings equiped. It is reliable in orientation, stable in working.

-

What is a pellet press?

Pellet presses, aslo known as pellet mills are used for the compression of dusty materials into solid pellets, sometimes known as bio-pellets for heating.

-

What is small pellet press?

The small pellet press is flat die pellet press with smaller capacity.

-

How big is a pellet press?

Pellets presses /pellet mills are available in from 7.5kw to 30kw.

-

What can the pellets used for?

Pellets can be used in the production of animal feeds, or as fuel pellets for use in a pellet stove or boiler.

-

What are the pellets made from?

Pellets can be made from wood / sawdust / plastic / foam / wheat / barley / cotton and fibre waste. They also need a wet ingrediant, such as steam or molasses.

-

What size pellets are produced?

The length and diameter of the pellets are adjustable according to the size of the die in the pellet press.

-

What is the cost of pellet press?

Different capacity, different price.

-

How do you deliver the pellet presses?

Transport and worldwide shipping is available.

-

Are the pellet presses new or used?

All the machine are used with warranty available, advice is free.

-

How are the pellets made?

The pellets are made by compacting the mash or meal into many small holes in a die. The die is usually round and the pellets are pushed from the inside out or opposite.

-

What is a oil press?

Oil press is a machine tool for processing oil extraction.

-

What is the capacity of oil press?

The oil press produced by us have different capacities suitable for small, middle and big oil mills.

-

What is the kind of oil press?

There are three types of oil presses classified by the structures: small scale oil press, automatic combined oil press and big scales oil press with cooker.

-

What is the raw material for oil press?

The raw material can be various vegetable plants such as ground nuts,beans,rape and cotton seeds, sesame, olive, sunflower, coconuts, and grass seeds etc

-

How to make vegetable oil from small oil presses?

The vegetable oil press of small capacity is composed with rings and screw in press chamber. There is control panel on the oil press. If you want to make oil from raw materials, you should clean them firstly, to remove the dust,stone and other impurity. When raw material prepared, you should let the oil pressing machine runing empty for a while for pre-heating of chamber. That can help the oil extracted out more successfully. After pre-heating for several minutes, you can feed material into the feeder of oil press. You can get the meal press for several time till there is no much oil in the meal.

-

How many kinds of vegetable oil presses?

The vegetable oil press mainly has three kinds from their structures: big scale oil press, small oil press and automated oil press combined with filter barrels. The big scale oil presses are applied in large oil mills. The small oil presses can be used for family to medium and small oil pressing workshop. The automated oil press combined with filter barrels are designed for personal use, which can save manpower from pressing and cleaning oil.

-

What is a biomass briquette press?

Biomass Briquette Press is a bio-charcoal bars making machine.

-

What is the capacity of biomass briquetting press?

The biomass briquette presses produced by us have three models. The output of them is as 80-120kg/hour, 120-150kg/hour, 180-230kg/hour.

-

What is the kind of oil press?

There are three types of oil presses classified by the structures: small scale oil press, automatic combined oil press and big scales oil press with cooker.

-

What is the raw material for biomass briquette press?

The biomass material can be various agro-forestry waste like wood chips, sawdust, wheat straw, rice husk and other biomass material.

-

What is the final products from biomass briquette machine?

The final products from bioamss briquette machine is sawdust bar. After carbonizing in kiln, they can be charcoal briquettes for barbeque in the open air or special for restuarant. The diameter of biomass briquettes can be 40mm to 110mm with different shapes. Such as square, quinquangular column, hexagonal column and other shapes. But hexagonal briquette bar is mostly advised.

-

What is Sawdust Briquette Charcoal?

Sawdust Briquette Charcoal is charcoal bar made by biomass briquette press of either hexagonal or square cross section with a center hole. The piston sawdust briquette charcoal have holes in the center. Size and shape of charcoal are manufactured to the general requirement of each country. Generally, square charcoal is in great demand in Japan whereas most buyers in Korea generally accept the hexagonal shape.

In Jan. 2018, a Canada biomass equipment dealer ordered 20 sets of Electric pellet machines from Agico group. These products have been delivered on time. ...

Agico group built a wheat flour mill plant In Colombo, Sri Lanka. It includes destoners, flour mill and batching system, etc. The production capacity is 80t/d....

AGICO has complete a 2ton/h sawdust pellet production line in Bulgaria. It includes wood debarker, hammer mill, rotary dryer, ring die pellet mill, pellet cooler, etc. ...