Mine / Coal Powder Briquette Press

Briquetting Technology

Briquetting is to transform powdery or granular material into larger briquette with different shapes, such as pillow, oval, square, cubic, round shape etc. The charcoal briquette making into different shapes is accomplished by compacting the materail into mould pressed by a pair or two pair of rollers. The pressure for ?charcoal briquetting machine can be adjusted according to the characteristics of the processed materials by mechanical or hydraulic.

Anyway, briquetting is the only one way to change the powdery material into briquettes which is suitable for transporting, in the meantime, this way also saves engery.

Suitable Material for Briquetting:

Color and Black Metallic Mine Powder:

Iron scale, Iron sludge, Precipitator dust, Iron concentrate, Raw material powder,

Manganese ore fines, Silicomanganese alloy. Etc.

Coal

Coal powder, Coke powder, Slime peat, Middle coal, lignite etc.

Other material:

Charcoal powder, Fireproof material, Desulfurized gypsum,Dolomite etc.

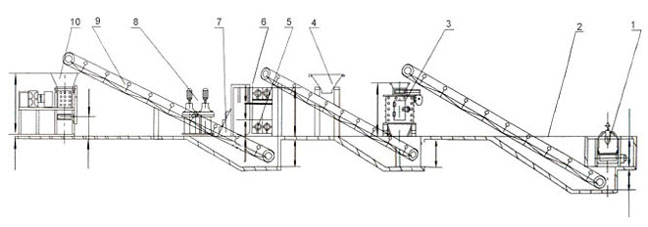

Mine / Coal Briquette Press

- Tank Metering Feeder

- Horizon

- Vertical Grinding Mill

- Dry Power Metering Feeder

- Tank Mixer

- Binder Valve

- Binder Pump

- Tank for Bond

- Rubber Belt Conveyor

- Briqette Press