Track spike

Track spike, also known as rail spike, is a large nail with an offset head that is used to secure the rails and the base plate to the sleepers. In general, nails have different shapes and functions, such as dog spikes, screws, Ss series sleeper screws, square head screws, hexagonal screws, double-headed screws and other shapes. Among these various railway nails, dog spikes and screw nails are the two most common types.

Track spikes are made from carbon steel or stainless steel according to different utility. Meanwhile, the spikes’ surface can be plain, black, hot dipped galvanized, or galvanized to meet the customers’ requirement.

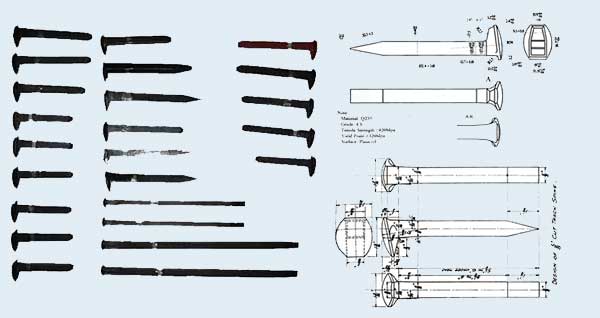

Dog spike

Dog spike has another name of cut spike. It features an L-shaped head that looks like a dog’s head and a with a square handle that is tilted to fit the top surface of the rail base. Typically, various sizes of nails are provided to meet the different requirements of the penetration length of the spikes. For smaller track sections, 5/8 "* 6" and 9/16 "* 5-1 / 2" are the two most common types of dog spikes, usually packed in 200 lb barrels or 50 lb kegs.

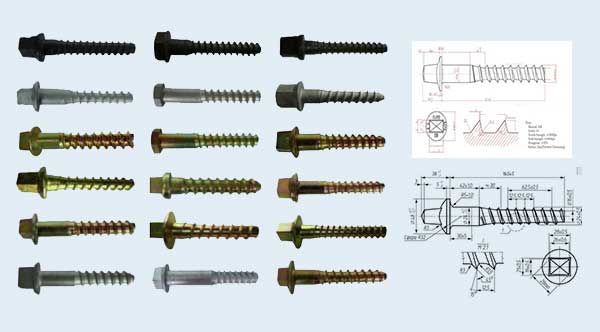

Screw spike

Screw spikes are usually used to fix concrete sleepers, so it is also called sleeper screw, rail screw or lag bolt. They can be screwed into the plastic ferrules casted in the concrete sleepers, or used in rails with wooden sleepers like in America and Canada. Unlike dog spikes, according to different international standards and specific geographical requirements, Screw Spikes are varied in thread profiles, length, diameter and drive head.

- Specification: 5/8×6 '', 9/16×5-1/2 '', 3/8''×3-1/2 '', 1/2×3-1/2 and other kinds.

- Material: A3, Q235, 45#, 55#, etc.

- Surface: According to customer’s needs.

- Standard: According to customer’s drawings or samples.

Production Process of screw spikes

Raw Material—Wiredrawing—Rod Cutting—Head Forming—Edge Cutting—Thread Rolling—Heating Treatment—Surface Finish—Inspection—Packing—Shipment

Ss series sleeper screw

Ss series sleeper screw is one of our best selling products, below are the dimensions of Ss series sleeper screws.

| Type | Specification | Weight/kg | Surface | Standard |

|---|---|---|---|---|

| Ss1/130 | M22*130 | 0.451 |

Natural, Zinc, Paint, Oil, or based on your needs. |

UIC, AREMA, GB, or based on your drawings or samples. |

| Ss1/150 | M22*150 | 0.478 | ||

| Ss2/180 | M22*180 | 0.595 | ||

| Ss5/150 | M24*150 | 0.545 | ||

| Ss6/150 | M26*150 | 0.702 | ||

| Ss7/180 | M24*180 | 0.636 | ||

| Ss8/140 | M24*140 | 0.528 | ||

| Ss8/150 | M24*150 | 0.548 |

Square head screw spike

As its name, this type of railroad spikes has a square head on one side and screw thread on the other side.

| Type | Specification | Material | Surface | Standard |

|---|---|---|---|---|

|

Square head screw spike |

M22*145 | 45# | Natural | UIC |

| M22*155 | 55Q | Zinc | AREMA | |

| M22*165 | Q235 | Paint | DIN | |

| M22*185 | or | Oil | GB | |

| M22*195 | According to your needs. | According to your needs. | or | |

| other kinds | According to your drawings or samples. |

Hexagon screw spike

Hexagon screw spikes include several different sizes such as: M22*145, M22*155, M22*165, M22*185, M22*195 and so on. Below are the parameters of hexagon screw spikes:

| Grade | 4.6 | 5.6 | 8.8 | 10.9 |

|---|---|---|---|---|

| Material | Q235 | 35# | 45# | 40Cr |

| Mechanical |

Tensile strength: Tensile strength: ≥ 400Mpa |

Tensile strength: ≥ 500Mpa |

Tensile strength: ≥ 800Mpa |

Tensile strength: ≥1000Mpa |

|

Yield strength: ≥ 240Mpa |

Yield strength: ≥ 300Mpa |

Yield strength: ≥ 640Mpa |

Yield strength: ≥ 900Mpa |

|

| Elongation: ≥ 22% | Elongation: ≥ 20% | Elongation: ≥ 12% | Elongation: ≥ 9% | |

| Cold bending: 90 degree | ||||

| Without Crack | ||||

| Surface | Plain (oiled) , Oxide black, Zinc, HDG, Wax, Bitumen, Dacromet, Sherardizing | |||

Double-head screw spike

As the name implies, double-head screw spike has 2 screw heads on both sides of the nail. It is commonly used in Nabla clamping system, especially for Africa. In order to achieve strict bending standard, it adopts straightened special raw materials, which presents no crack after being bended for 30 degrees.

| Size | 23×174 |

|---|---|

| Grade | 4.6, 5.6, 8.8, 10.9 |

| Raw Material | Q235, 35#, 45# |

| Surface Treatment | Plain (oiled), Bluing, Zinc, HDG, etc. |