Mobile Pellet Plant

The mobile pellet plant is our self-developed product, manufactured for professional pelletizing. As our star product, it integrate hammer mill, material storage bin, screw feeder, ZLSP300B/400B R-type pellet mill, vibrating screen and scraper conveyor on one foundation, so that it is convenient to move and use.

It can not only pelletize sawdust, stalks and straw, but also process forage and fodder for animals.The Raw Materials or feedstocks for mobile pellet plant cover wood chip, sawdust, stalk, straw, twig, rice husk, peanut shell, forage, etc.

Advantages of Mobile Pellet Plant

- Easy operation: You can operate the mobile pellet plant on your own by pushing buttons.

- Wide application: It applies to various biomass materials and working conditions.

- High yield rate: the pneumatic conveying system, dust control device and cooler on the scraper ensure full use of raw materials.

- Portability: Thanks to the small volume and compact structure, the mobile pellet plant is easy to move.

- Durability: The key parts come from Schneider, a reliable and trustable supplier.

Specifications of Mobile Pellet Plant

| Model | Capacity(kg/h) | Pellet Diameter(mm) | Power(kw) | Size(mm) |

|---|---|---|---|---|

| MPL300 | 250-350 | 6-12 | 41.25 | 3500*1960*3500 |

| MPL400 | 350-450 | 6-12 | 49.25 | 3500*1960*3500 |

Process flow of Mobile Pellet Plant

Pulverizer-----Cyclone Separator-----Surge Bin----Screw Elevator----Feeder----PMZL-300B Pellet Mill-----Vibrating Screen-----Finished Products-----Bag Type Dust Collector

Pulverizer

The mobile pellet plant adopts hammer mill. For the pulverizing section, the output of which is due chiefly to the size and moisture content of the feedstock and mesh size. Here are the main technical parameters

| Model | Power(kw) | Yield(kg/hr) | Qty of the hammer blades |

|---|---|---|---|

| TFS-420 | 7.5 | 550-700 | 16 |

| Weight(kg) | Packing size | Other references | |

| 280 | 1090*820*1100 | Capable of pulverizing lumber with the diameter less than 30mm. | |

Storage bin

The bin is for feedstock storage. Here are two ways of putting the feedstock into the bin. On the one hand, thanks to air flow, the pulverized material will fall into the bin via cyclone separator; on the other hand, feedstock in qualified size can be added in straightforward from the bin inlet.

Screw elevator

The screw elevator, also known as screw conveyer hereby, is used to convey materials driven directly by the motor.

Feeder

The feeder, more like shape and structure of the screw conveyer aforementioned, is for putting feed into the pellet mill continuously.

The TRBs on each end shall be lubricated every four working hours. Check oil level of the reduction gearbox on the feeder monthly, with the oil taking up one third of the gearbox. If not, please add it.

PMZL-300B pellet mill

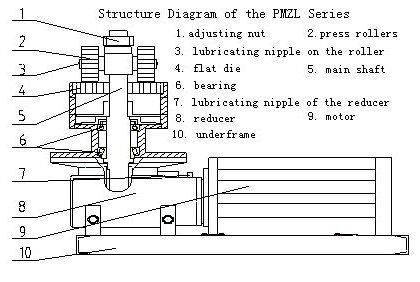

1.Adjusting nut 2.press rollers 3. lubricating nipple on the roller 4. flat die 5. main shaft 6 bearing 7.lubricating nipple of the reducer 8. reducer 9. motor 10. underframe

Vibrating screen

As a sifter, the vibrating screen also can help to cool pellets down at the same time. The pellet crumb and scraps collected under the wire mesh shall be cleaned away timely. Simultaneously, qualified pellets will be discharged at the rear outlet. During the operation, the sifter works stably.

What’s more, vibrating frequency can be converted. However, the rotating directions of the two motors shall keep opposite.

Bag type dust collector

It’s mainly for collecting powdery materials and dusts. Thanks to the collector equipped with an induced fan, the ash content of the exhausted air will remarkably reduced on one hand, and on the other, not only can pellets be cooled in the meantime, but the working environment can be kept as much clean as possible.

The fan possessing power of 3 KW and air volume of 2664-5268m3/h can suck powdery crumb and dust into the collector and filter them which will then be exhausted out to the open air. The whole set of bags can vibrate automatically and the shaking time and interval can be preset by simply adjusting the time relay. But crumb and dust will be piled up on the drawer of the collector. Please dump them timely or put them back to use into the surge bin.

You are welcome to contact us for more details of this small mobile pellet plant.