Biomass Pellet Mill

Why use Biomass for Pelletizing?

Biomass is any living or recently dead material that can be used as fuel. This includes any wood and waste wood products, also energy crops such as Miscanthus, Switch Grass, Reed Canary Grass, Oilseed Straw to name but a few.

Biomass is a carbon neutral fuel, which means no extra carbon is released into the atmosphere when burnt, unlike fossil fuels. Biomass can play a crucial role in reducing global warming. Biomass is a cheap fuel to produce, much biomass is free, in the form of waste wood products.

Raw Material for Biomass Pellet Mill

The picture referred to biomass pellets respectively made of rice hull, bamboo, wood shaving, saw dust, waste paper, wood sticks, and sawdust. All of these belong to biomass material. Besides, any type of agro-forestry waste can be used, which becoming a new type of biofuel. The choice of raw material is very important that is because each material has a different heat value, ash content and corrosive qualities.Each material has to be prepared slightly differently to make quality pellets.

Your choice of biomass should be based primarily on what you have available to you, but also what your boiler or stove can burn successfully without complications. Check the properties section for a summary of some biomass fuel properties.

What size of Biomass can be used for Biomass Pellet Mill

The PelHeat unit is equipped with a hammer mill which breaks the raw material down into a uniform size (3mm-6mm). The hammer mill can process straws and grasses, however for the unit to accept wood for example it must be in a chipped form, or have a diameter less than 1 inch.

Equipments for Making biomass pellets

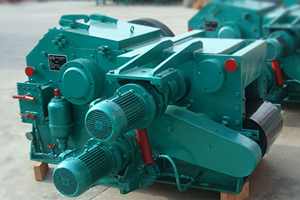

Biomass pellet mill is specialized equipment designed for making biomass pellets. According to different inner structure, it can be divided into flat die and ring die two types. Flat die pellet mills are smaller in size, which applies to home and small workshop use. It features low cost and power consumption, steady output and easy operation. Ring die pellet mills have larger size and higher capacity, which is a economical choice for large-scale production. Both types are capable of processing wide range of biomass materials. The pellets has high hardness and slippery surface, with the diameter of 6mm, 8mm and 10mm.

Ring Die Biomass Pellet Mill specifications

| Model | BPM35 | BPM420 | BPM508 |

|---|---|---|---|

| Capacity | 500-700kg/h |

Sawdust: 1.2-1.5T/H Straw: 2.0-2.5T/H |

Sawdust: 1.5-2.0T/H Straw:2.5-3.5T/H |

| Main Motor Power | 30*2kw | 90kw | 110kw |

| Feeding Motor Power | 0.75kw | 1.5kw | 1.5kw |

| Forced-feeding Motor Power | 0.75kw | 3kw | 2.2kw |

| Weight | 2200kg | 3000kg | 3700kg |

| Packing Size | 1850*1950*1500mm | 1100*2700*2000mm | 1200*2900*2000mm |

Flat Die Biomass Pellet Mill specifications

| Model Number | Power(kw) | Output(kg/h) | N.W./G.W.(kg) | Package Size(mm) |

|---|---|---|---|---|

| ZLSP150B | 3phase, 5.5 | 50-100 | 95/100 | 800*450*700 |

| ZLSP200B | 3phase, 7.5 | 80-120 | 200/230 | 1050*480*930 |

| ZLSP230B | 3phase, 11 | 120-200 | 290/320 | 1180*540*1000 |

| ZLSP260B | 3phase, 15 | 160-250 | 320/360 | 1240*540*950 |

| ZLSP300B | 3phase, 22 | 250-400 | 350/380 | 1300*560*1100 |