Large Pellet Mill Plant

What is Pellet Mill Plant?

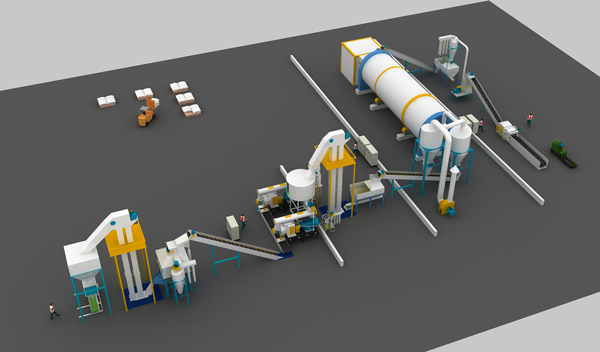

Pellet mill plant is the combination of a series of biomass material processing equipments, including Log splitter, crusher/hammer mill, dryer, large pellet mill, pellet cooler, conveyor, pellet packing machine, etc.. As it is mainly used to produce wood pellets, it is also called wood pellet line.

Wood pellet line can process a wide range of raw materials, such as hard wood, soft wood and their mixture, saw dust, bamboo waste, EFB (Empty Fruit Bunch), coconut shell, sugarcane bagasse, and many other biomass material.

Large Pellet Mill Plant 1-30ton/h

Pellet mill plants have different equipments mix according to various production requirements. You don’t have to put together all the equipments above. Our turn-key solution can arrange the best procedures and machines for you. We provide full services for Pellet Mill Plant from process design, auto-control, layout, manufacture and installation to after-sales guarantee. We also provide auxiliary equipments and spare parts for wood pellet mill.

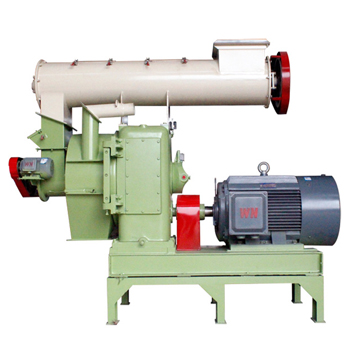

Ring Die Pellet Mill: the core equipment

Specifically, we provide large, small and mobile three different product series. As the name indicate, large pellet mill plant has the largest capacity, especially suitable for mass production. The key equipment of large pellet mill plant is ring die pellet mill. It adopts high-strength material to achieve stable performance, high output, long service life and low noise. By combining several ring die pellet machine, the production can reach up to 20t per hour.

| Model |

Capacity (kg/h) Sawdust/Stalks |

Main Motor (kw) | Feeding Motor (kw) |

Forced-feeding Motor (kw) |

Dimension (mm) | Weight (kg) |

|---|---|---|---|---|---|---|

| BPM35 | 500-800 | 30*2 | 0.75 | 0.75 | 2150*1950*1900 | 2200 |

| BPM420 | 1200-1500/1500-2000 | 90 | 1.5 | 3 | 2600*1000*2000 | 3400 |

| BPM508 | 1500-1800/2000-2500 | 110 | 1.5 | 3 | 2990*1200*2410 | 4500 |

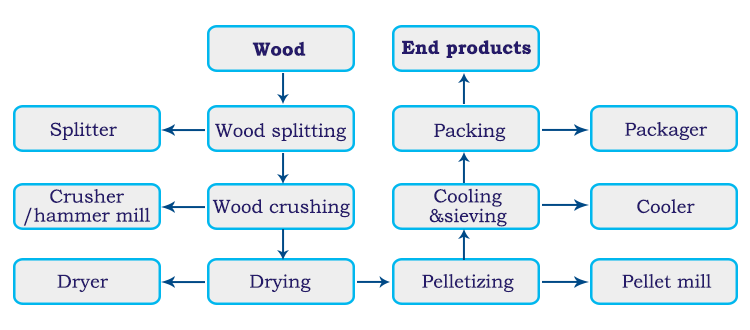

Flowchart for Pellet Mill Plant

The production flow is generally wood splitting, crushing, drying, pelletizing, cooling, sieving and packing. Each process is matched with a corresponding device, like wood splitter, hammer mill, dryer machine, pellet mill, cooler and packager.

Crushing

When the thickness of raw wood material is more than 10mm, and length*width is more than 50 * 50mm,we need to crush the material into small pieces, then crush the small pieces into wood powder with diameter less than 3mm by Hammer Mill (Crusher).

Drying

The best moisture content to pelletizing is about 13-15%. Our Rotary Dryer is made up of Stove and Main Rotary Dryer, which can realize the goal of reducimg the moisture from 60% to 10%. Our stove is fueled by coal, which can save electricity consumption largely.

Pelletizing

The Pellet Mill is the essential equipment for making wood pellets, which have the following features:

- The lubrication system for wood pellet mill adopts the tracing and inspecting system controlled by the microcomputer. When the temperature of the bearing is over the normal temperature, the microcomputer will start the Auto-Lubrication System to lubricate the bearings, which will completely solve the problem of lubricating roller depending on the operation experience. The Lubrication System is made up of the tracing and inspecting system controlled by the microcomputer, auto-lubricating system on time and compelled lubricating system by hand.

- Driving Gear adopts the high precision gear transmission structure. The wear bearing is SKF from Sweden. The ring die adopts the hoop fastening method, which is increasing the speed of discharge compared with the past bolt fastening method. As a result, the capacity is 10%-15% higher than the belt transmission structure.

- As for the ring die and roller of the wood pellet mill, we have the fine machining with the alloyed steel. And our heating treatment is also different from the other domestic manufacturer.Our carburizing treatment make the depth of hard facing to 2mm, which increace the quality of anti-abrasion of the ring die and roller more than 10 times. As a result, it can save the production cost largely.

- Additionally, we have developed a kind of new Air Current Rotary Dryer, which can reduce about 30% of energy consumption compared with the old Rotary Dryer.

Cooling

After the pelletizing process, the temperature of the wood pellet is about 60-80 degree, and the moisture content of the wood pellet is about 15%.Then we need to use Cooler to reduce about 3%-4%of the moisture so that the wood pellet would be easy to store.

But considering the feedback from some foreign clients, the local climate is very humidity; they hope to cool the wood pellet with moisture 7%-8%. In order to satisfy different needs from different clients, we develop one kind of new Stabilizer Combined Cooler.

Packing

After cooling, the wood pellet mill not directly enter into the fuel process, avoiding the wood pellet affected with damp. The packing process is necessary. In this process, we assemble our domestic best Semi-Auto Packing Machine to you.