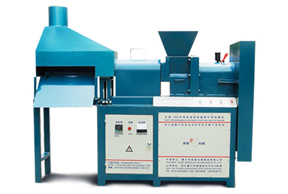

Disc Huller for Cottonseed| Peanut| Soybean

We call it Decorticator also which is used not only in de-hulling the shells of oilseed like cottonseed, peanut inshell, also in crushing oilseed like peanut, soybean etc.

Features:

1)Hulling Ratio reach to 99% and no whole seed left for second dehulling

2)The short lint is moved when de-corticating. In this complete line, we match the Fans & Cyclone which can collect the short lint, so it’ll be easier to separate the Hulls & Kernels and increase the protein content in cakes & meal. The other advantage is to keep the workshop in good clean working condition.

3)It’s convenient to operate and send back the foreign hard material.

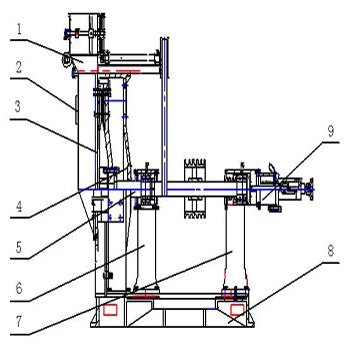

Stucture of Disc Huller

Model GCBK71/91

1.Feeding Hopper & base 2. Feeding Leader & front cover 3. Disc

4.Behind Cover 5.Main shaft 6. Front Bearing Supporter

7. Behind Bearing Supporter 8.Base 9.Adjusting System

Hot Selling Model GCBK127

This is the biggest model which is used in large oil mill. We got patent on structure & material. Through adding Stirring Wheel between the Fixed Disc & Moving Disc, increase the working area, thus, the production efficiency & capacity go up in times. Except the other feature of our traditional products, the special character is:

higher capacity however power consumption reduced to 7.4KW/T material.

|

Model |

Capacity (t/d) |

Power |

Weight (kg) |

Dimension(mm) |

|

GCBK71 |

35 |

18.5 |

1100 |

1820*940*1382 |

|

GCBK91 |

50-60 |

30 |

1700 |

2160*1200*1630 |

|

GCBK127 |

100-170 |

37-45 |

2600 |

2400*1620*1980 |

The 117th China Import and Export Fair will be held during Apr.15th ~19th, 2015. Our company will attend it as usual....

The 117th China Import and Export Fair will be held during Apr.15th ~19th, 2015. Our company will attend it as usual.... >>into